Reducing Greenhouse Gas (GHG) Emissions at Our Business Sites

Our Approach

Considering the prevention of global warming an important issue, the Fujitsu Group formulated its medium- to long-term environmental vision, the Fujitsu Climate and Energy Vision, which aims to eliminate all CO₂ emissions from our business activities by 2050. However, we have decided to move the target year forward to 2030.

Among GHGs, our business sites (plants and offices, as well as datacenters) primarily emit CO₂ when energy (electricity, fuel oil, gas) is used, and perfluorocarbons (PFCs), hydrofluorocarbons (HFCs), sulfur hexafluoride (SF6) during the manufacturing processes and PFCs and HFCs from fluorocarbon leakage. We will set reduction targets in addition to complying with the relevant laws, and we are striving to reduce and control the volume of use and emission of these gases.

Reducing CO₂ Emitted During Energy Consumption

About 99% of the Fujitsu Group’s total GHG emissions arise from CO₂ emissions due to energy consumption. Therefore, we continuously promote the following energy-saving measures to reduce CO₂ emissions.

- Appropriate operation of equipment, improvement in management, and energy-saving measures focused on motive-power facilities (introduction of free cooling, inverters and energy saving equipment, fuel conversion, etc.)

- Increasing efficiency by reviewing the manufacturing process (innovations in production, development of green production technology)

- Maintaining appropriate room temperature for office air conditioning, saving electricity used in lighting and office automation equipment, and switching to LED lighting

- Measuring energy consumption for visualization and promoting use of the data so collected

Reducing Emission of GHGs Other Than CO₂

As for GHGs other than CO₂, the Fujitsu Group mainly uses perfluorocarbons (PFCs), hydrofluorocarbons (HFCs) and sulfur hexafluoride (SF6) at the manufacturing divisions. We are taking continuous steps to switch to gases with lower global warming potential (GWP) and install equipment to remove harmful gases in our new and existing production lines. We also carry out inspections and maintenance to comply with relevant laws regarding PFCs and HFCs emissions resulting from fluorocarbon leaks from air conditioning equipment.

FY2024 Performance

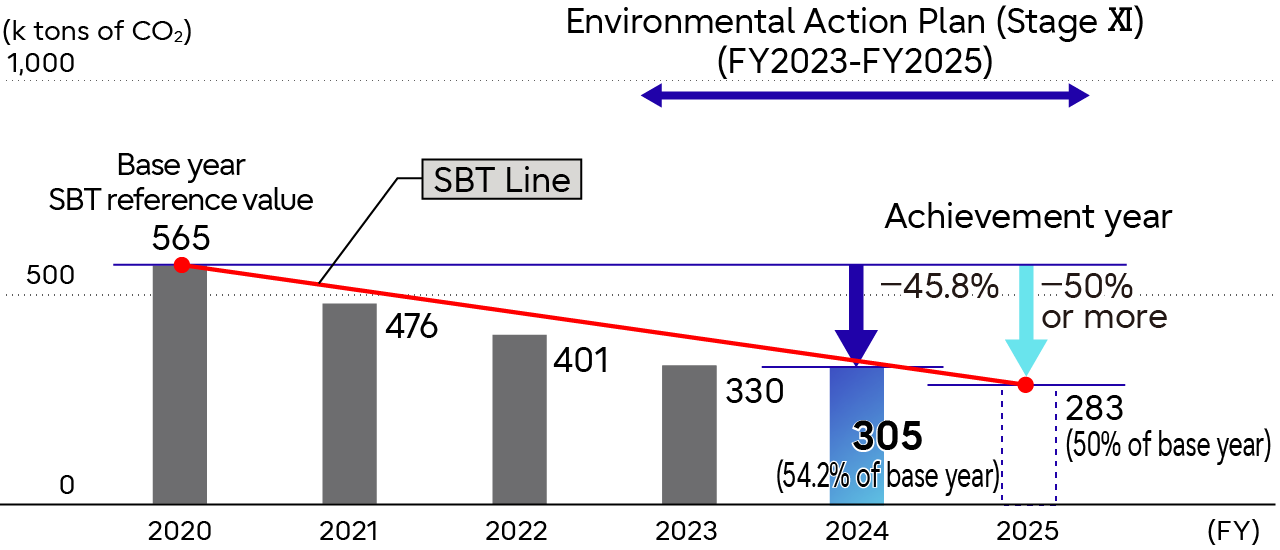

| Targets under the Fujitsu Group Environmental Action Plan (Stage XI) | FY2024 result |

|---|---|

| Reduce GHG emissions of our business sites to 50% or less of the base year (FY2020) level. (FY2024 target: 40% reduction ) (*1) | 45.8% reduction (*2) |

- *1: Target organizations: Business sites owned by Fujitsu and the Fujitsu Group. Includes major data centers.

- *2: GHG emissions reduction rate based on market standards

Promoting Reduction in CO₂ Emitted During Energy Consumption

We continue to invest in energy-saving equipment (introduction and upgrade of BAT (*3) equipment, mainly for air conditioning and lighting) and ensure their appropriate operation at the facilities at all business sites. We are also streamlining our production processes, saving electricity used for air conditioning, lighting and automation in offices, making energy consumption visible, and leveraging measurement data.

For instance, as for lighting equipment investments, we have contributed to the reduction of CO₂ emissions by 1,944 t-CO₂ through the continuous and efficient deployment of high-efficiency LED lighting. We also improved facility operations (2,168 t- CO₂) by reviewing air conditioning equipment operating conditions, such as switching to more efficient equipment, controlling the number of units, and suspending operation of pumps and air conditioning devices. Furthermore, we also contributed to reductions (3,744 t-CO₂) through the introduction of high-efficiency chillers and the improvement of chilled water supply efficiency. Through our own efforts, we carried out measures to reduce emissions by roughly 8,000 tons-CO₂ (2.4% in comparison to last fiscal year).

As a result of these initiatives, we reduced our GHG emissions according to market standards in keeping with SBT, which is an objective in the Environmental Action Plan (Stage Ⅺ), by 45.8% compared to the baseline year (7.5% reduction in comparison to our emissions in FY2023).

- *3: BAT (Best Available Technologies): Usable state-of-the-art technologies to reduce GHGs.

- *4: Environmental Action Plan (Stage XI) performance values for the reference year (FY2020) and FY2024 are the total values for business sites targeted by the Environmental Action Plan (Stage X).

- *5: CO₂ conversion factors of purchased electricity are market standards for both the reference year (FY2020) and FY2024 performance values.

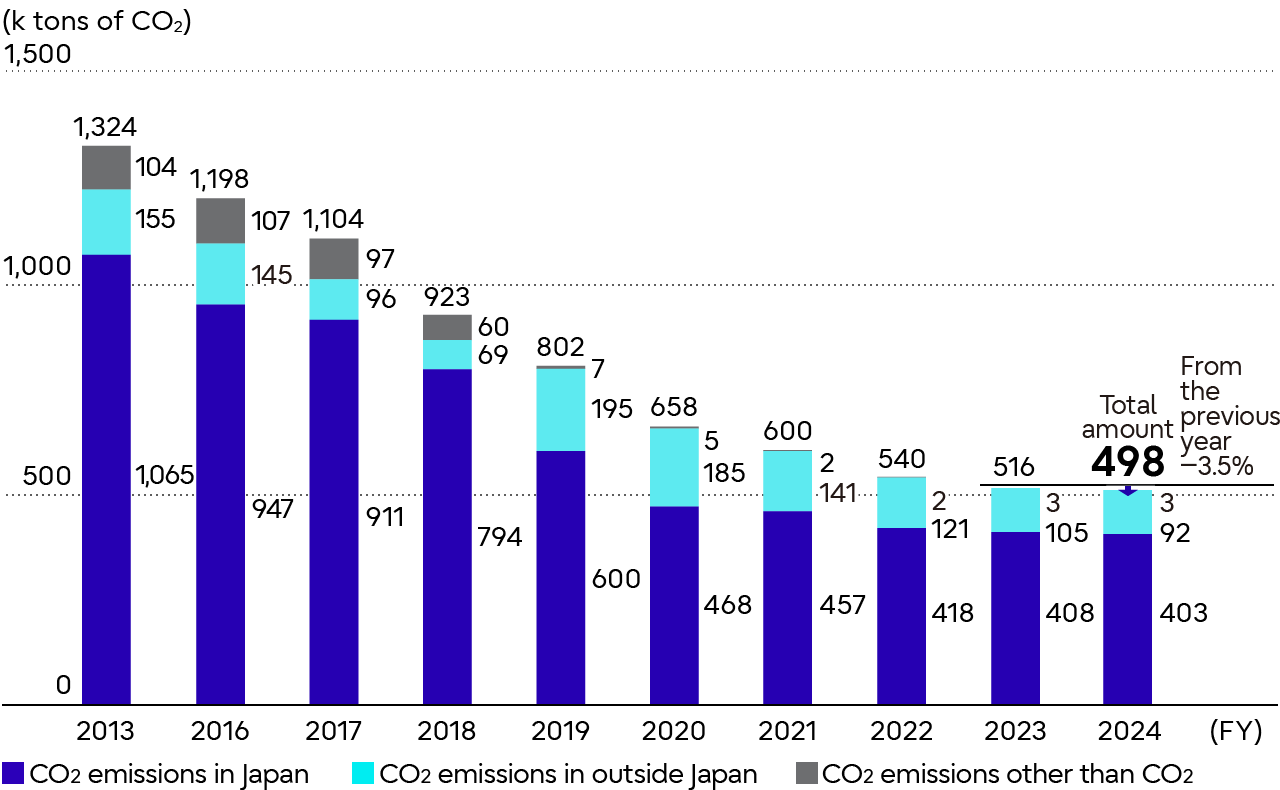

Total Emissions of 498 ktons-CO₂ in FY2024

Our total GHG emissions in FY2024 were 498 ktons-CO₂ (output level per sales amount: 14.0 tons-CO₂/100 million yen). They decreased by 3.5% in comparison to FY2023.

-

*6: CO₂ emissions in Japan and overseas: The CO₂ conversion factor for purchased electric power in performance reports has been calculated with a fixed value of: In Japan - 0.570 tons-CO₂/MWh from FY2013 to FY2015, 0.534 tons-CO₂/MWh for FY2016, 0.518 tons-CO₂/MWh for FY2017, 0.497 tons-CO₂/MWh for FY2018, 0.461 tons-CO₂/MWh for 2019, 0.444 tons-CO₂/MWh for FY2020, 0.441 tons-CO₂/MWh for FY2021, 0.436 tons-CO₂/MWh for FY2022, 0.437 tons-CO₂/MWh for FY2023, and 0.421 tons-CO₂/MWh for FY2024.

Overseas – The same coefficients as those used in Japan are applied from FY2013 to FY2018, and from FY2019 onwards, values are calculated using the latest IEA data (by country ) for the relevant FY. - *7: Emissions other than CO₂: These are converted to equivalent amounts of CO₂ using the global warming potential (GWP) for each gas.